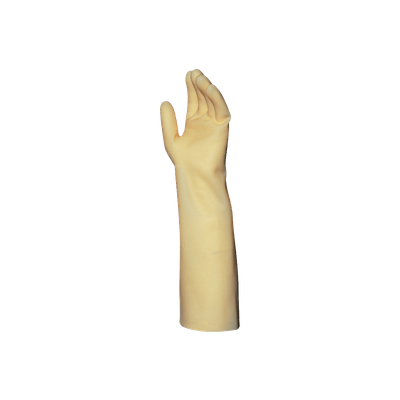

AdvanTech 517

Een exclusieve tripolymeer die 100% comfort biedt voor optimale mechanische en chemische resistentie

-

CAT. 3

0334

0334

-

1110X

1110X

-

Type B

KST

KST

-

Specifieke voordelen

Bescherming van de huid

Bescherming van de huid

- uitstekende weerstand en sterke chemische bescherming tegen vele chemische producten: exclusieve Trionic formule bestaand uit natuurlijke latex, neopreen en nitril

- Hypoallergeen

Gegarandeerde kwaliteit

Gegarandeerde kwaliteit

- Productieproces garandeert een zeer kleine hoeveelheid vervuiling: deeltjes, niet-vluchtige en extraheerbare resten => compatible met ISO 4 klasse.

- Siliconenvrij om sporen en defecten op metalen platen en glas te voorkomen voorafgaand het lakken

Extra voordelen

Extra voordelen

- Klasse 100 (ISO 5) compatibel

Praktisch

Praktisch

- Uitgebreide productlijn voor alle toepassingen: wijde manchet voor dubbele handschoenen, extra lengte voor bescherming van de onderarm

Productgegevens

| Materiaal | Natuurlijke latex, neopreen en nitril |

|---|---|

| Kleur | beige |

| Binnenafwerking | Gechloreerd |

| Buitenafwerking | Reliëftextuur |

| Lengte (cm) | 36 |

| Dikte (mm) | 0.50 |

| Maat | 6 7 8 9 10 |

| Verpakking | 1 paar/zak 12 paren/zak 72 paren/karton |

Chemicaliëngrafiek

Algemene beoordeling van chemische bescherming

De beoordeling van de bescherming houdt rekening met de invloed van zowel permeatie als degradatie in een poging om gebruikers een algemene richtlijn te verstrekken wanneer zij onze handschoenen gebruiken met specifieke chemicaliën.

Betekenis kleuren:

De gegevens van chemische testen en de algemene beoordeling van de chemische bescherming mogen niet gebruikt worden als absolute basis bij de keuze van handschoenen. De werkelijke gebruiksomstandigheden kunnen de prestaties van de handschoenen beïnvloeden wat tot andere resultaten dan bij de laboratoriumtesten kan leiden. Naast chemische contacttijd

| Chemisch product | CAS # | Permeatietijd (minuten) |

Permeatie niveau |

Standaard | Degradatie niveau |

Beoordeling |

|---|---|---|---|---|---|---|

| 1,1,1-Trichloorethaan 99% | 71-55-6 | 7 | 0 | ASTM F739 | NT |

|

| 1,1,1,2,2,3,4,5,5,5-Decafluoropentaan 97% | 138495-42-8 | 13 | 1 | ASTM F739 | NT |

|

| 1,1,2-Trichloortrifluorethaan (Freon TF of Freon 113) 99% | 76-13-1 | 20 | 1 | ASTM F739 | 1 |

|

| 1,2 dichloorethyleen 98% | 156-60-5 | 2 | 0 | ASTM F739 | 2 |

|

| 1,3 Ethoxypropionaat (Ethyl 3-ethoxypropionaat) 99% | 763-69-9 | >480 | 6 | ASTM F739 | NT |

|

| 2-(2-[4-(1,1,3,3-tetramethylbutyl)fenoxy]ethoxy)ethanol 100% | 9002-93-1 | >480 | 6 | ASTM F739 | NT |

|

| 2-Butoxyethanol (Butyl Cellusolve) 99% | 111-76-2 | 53 | 2 | ASTM F739 | NT |

|

| 2-Butoxyethylacetaat (Butyl cellosolve acetaat) 85% | 112-07-2 | 35 | 2 | ASTM F739 | NT |

|

| 2-Ethoxyethanol (Cellosolve) 99% | 110-80-5 | 27 | 1 | ASTM F739 | NT |

|

| 2-Ethoxyethylacetaat (Cellosolve-acetaat) 99% | 111-15-9 | 14 | 1 | ASTM F739 | 4 |

|

| 2-Methoxyethanol (Methyl Cellosolve) 99% | 109-86-4 | 40 | 2 | ASTM F739 | NT |

|

| 2-Methoxyethanolacetaat (Methylcellosolveacetaat) 98% | 110-49-6 | 27 | 1 | ASTM F739 | NT |

|

| 2-Propanol (Isopropanol) 99% | 67-63-0 | 29 | 1 | EN 374-3:2003 | 4 |

|

| 4,4 - diamino-difenylsulfon 97% | 80-008-0 | >480 | 6 | ASTM F739 | NT |

|

| 4,4'-Methyleendianiline (MDA) 15% en 15% Methanol Mengsel | 101-77-9 | 19 | 1 | ASTM F739 | NT |

|

| 4,4'-Methyleendianiline (MDA) 15% in tolueen Mengsel | 101-77-9 | <15 | 1 | ASTM F739 | NT |

|

| Aceton 99% | 67-64-1 | 6 | 0 | ASTM F739 | 4 |

|

| Aluminium-ets Mengsel | NA | >960 | 6 | ASTM F739 | 4 |

|

| Aluminiumoxide Mengsel | NA | 55 | 2 | ASTM F739 | NT |

|

| Ammoniumfluoride 40% | 12125-01-8 | >480 | 6 | ASTM F739 | NT |

|

| Ammoniumfluoride 79% | 12125-01-8 | >480 | 6 | ASTM F739 | NT |

|

| Ammoniumhydroxideoplossing 29% | 1336-21-6 | 19 | 1 | EN 374-3:2003 | 4 |

|

| Aqua Regia Mengsel | 8007-56-5 | >480 | 6 | ASTM F739 | NT |

|

| Azijnzuur 99% | 64-19-7 | 29 | 1 | EN 374-3:2003 | 4 |

|

| Baker PRS-1000 Mengsel | NA | <20 | 1 | ASTM F739 | NT |

|

| Baker PRS-2000 Mengsel | NA | 130 | 4 | ASTM F739 | NT |

|

| Baker PRS-3000 Mengsel | NA | >480 | 6 | ASTM F739 | NT |

|

| Benzeen 99% | 71-43-2 | 4 | 0 | ASTM F739 | 1 |

|

| Butylacetaat 99% | 123-86-4 | 5 | 0 | EN 374-3:2003 | 4 |

|

| Chroomzuur 50% | 7738-94-5 | 60 | 2 | ASTM F739 | NT |

|

| Cyclohexanon 99% | 108-94-1 | 23 | 1 | ASTM F739 | 1 |

|

| Cyclopentanon 99% | 120-92-3 | 11 | 1 | ASTM F739 | NT |

|

| Dichloormethaan (methyleenchloride) 99% | 75-09-2 | >4 | 0 | ASTM F739 | NT |

|

| Dichromaat reinigingsoplossing Mengsel | NA | >480 | 6 | ASTM F739 | 4 |

|

| Diëthylamine 98% | 109-89-7 | 4 | 0 | ASTM F739 | NT |

|

| Diglycidylether van bisfenol 100% | 25068-38-6 | >480 | 6 | ASTM F739 | NT |

|

| Dimethylamine 35% | 124-40-3 | 53 | 2 | ASTM F739 | NT |

|

| Dimethylformamide 99% | 68-12-2 | 8 | 0 | ASTM F739 | NT |

|

| Dimethylsulfoxide 99% | 67-68-5 | 181 | 4 | ASTM F739 | 4 |

|

| Epichloorhydrine 99% | 106-89-8 | 4 | 0 | ASTM F739 | NT |

|

| Ethanol 95% | 64-17-5 | 21 | 1 | ASTM F739 | NT |

|

| Ethyleenglycol 99% | 107-21-1 | >480 | 6 | ASTM F739 | 4 |

|

| Ethyllactaat 95% | 97-64-3 | 29 | 1 | ASTM F739 | NT |

|

| Fenol 85% | 108-95-2 | 102 | 3 | ASTM F739 | 4 |

|

| Fluorwaterstofzuur 10% | 7664-39-3 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Fluorwaterstofzuur 40% | 7664-39-3 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Fluorwaterstofzuur 49% | 7664-39-3 | >480 | 6 | EN 374-3:2003 | NT |

|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Fosforoxychloride 99% | 10025-87-3 | <15 | 1 | ASTM F739 | NT |

|

| Fosforzuur 75% | 7664-38-2 | >480 | 6 | ASTM F739 | 4 |

|

| Fosforzuur 85% | 7664-38-2 | >480 | 6 | ASTM F739 | 4 |

|

| Gebufferd-oxide-ets Mengsel | NA | >480 | 6 | ASTM F739 | 4 |

|

| Hexamethyldisilazaan (HMDS) 98% | 999-97-3 | 18 | 1 | ASTM F739 | 1 |

|

| Kaliumhydroxide 50% | 1310-58-3 | >480 | 6 | ASTM F739 | 4 |

|

| Kaliumhydroxide-etsen Mengsel | NA | 24 | 1 | ASTM F739 | NT |

|

| Kerosine Mengsel | 8008-20-6 | 26 | 1 | ASTM F739 | 1 |

|

| KOH-ets Mengsel | NA | 278 | 5 | ASTM F739 | 4 |

|

| KTI Pad Etch Mengsel | NA | >480 | 6 | ASTM F739 | NT |

|

| KTI siliciumetsen Mengsel | NA | >480 | 6 | ASTM F739 | NT |

|

| Loodvrije benzine Mengsel | 8006-61-9 | 4 | 0 | ASTM F739 | 1 |

|

| Methanol 85% | 67-56-1 | 19 | 1 | ASTM F739 | 4 |

|

| Methyl Amyl Ketone 98% | 110-43-0 | 8 | 0 | ASTM F739 | 1 |

|

| Methyl-3-methoxypropionaat 100% | 3852-09-3 | 11 | 1 | ASTM F739 | 3 |

|

| Methylethylketon (2-Butanon) 99% | 78-93-3 | 4 | 0 | ASTM F739 | 3 |

|

| n-hexaan 95% | 110-54-3 | 3 | 0 | ASTM F739 | 1 |

|

| N-methyl-2-pyrrolidon 99% | 872-50-4 | 33 | 2 | EN 374-3:2003 | 4 |

|

| N-N dimethylacetamide 99% | 127-19-5 | 47 | 2 | ASTM F739 | NT |

|

| Nafta VM&P Mengsel | 8032-32-4 | 2 | 0 | ASTM F739 | 1 |

|

| Nafteenhoudend destillaat Waterstofbehandeld Licht Mengsel | 64742-53-6 | 161 | 4 | ASTM F739 | 2 |

|

| Natriumhydroxide 20% | 1310-73-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Natriumhydroxide 40% | 1310-73-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Natriumhydroxide 50% | 1310-73-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Propyleenglycol 99% | 57-55-6 | >480 | 6 | ASTM F739 | 4 |

|

| Propyleenglycolmonomethylether 99% | 107-98-2 | 26 | 1 | ASTM F739 | 4 |

|

| Propyleenglycolmonomethyletheracetaat (PGMEA) 99% | 108-65-6 | 47 | 2 | ASTM F739 | 3 |

|

| Salpeterzuur 10% | 7697-37-2 | >840 | 6 | ASTM F739 | 4 |

|

| Salpeterzuur 20% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Salpeterzuur 40% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Salpeterzuur 68% | 7697-37-2 | 299 | 5 | EN 374-3:2003 | 4 |

|

| Salpeterzuur 70% | 7697-37-2 | 307 | 5 | ASTM F739 | 4 |

|

| Salpeterzuur 90% | 7697-37-2 | 7 | 0 | ASTM F739 | NT |

|

| Siliciumtetrachloride 100% | 10026-04-7 | <15 | 1 | ASTM F739 | NT |

|

| Slope-ets Mengsel | NA | 260 | 5 | ASTM F739 | 4 |

|

| Tetrachloorethyleen (Perchloorethyleen) 99% | 127-18-4 | 3 | 0 | EN 374-3:2003 | 1 |

|

| Tetraethylorthosilicaat 100% | 78-10-4 | 25 | 1 | ASTM F739 | 1 |

|

| Tetramethylammoniumhydroxide 25% | 75-59-2 | >480 | 6 | ASTM F739 | 4 |

|

| Thionylchloride 99% | 7719-09-7 | <15 | 1 | ASTM F739 | NT |

|

| Tolueen 49% Methylisobutylketon 34,5% Methylethylketon 16,5% Mengsel | NA | 1 | 0 | EN 374-3:2003 | NT |

|

| Tolueendi-isocyanaat (TDI) 80% | 584-84-9 | 27 | 1 | ASTM F739 | NT |

|

| Trimethylfosfiet 97% | 121-45-9 | 10 | 0 | ASTM F739 | NT |

|

| Waterstofperoxide 30% | 7722-84-1 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Xyleen 99% | 1330-20-7 | 3 | 0 | EN 374-3:2003 | 1 |

|

| Zoutzuur 10% | 7647-01-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Zoutzuur 37% | 7647-01-0 | 454 | 5 | ASTM F739 | 4 |

|

| Zwavelzuur 10% | 7664-93-9 | >900 | 6 | ASTM F739 | 4 |

|

| Zwavelzuur 96% | 7664-93-9 | 41 | 2 | EN 374-3:2003 | 3 |

|

* niet-genormaliseerd resultaat

Meer handschoenen

AdvanTech 514

Een exclusieve tripolymeer die 100% comfort biedt voor optimale mechanische en chemische resistentie

Contact

If you would like to ask us a commercial question about our products or if you would like to have more technical information about our gloves and their use, please fill out one of the forms proposed below.